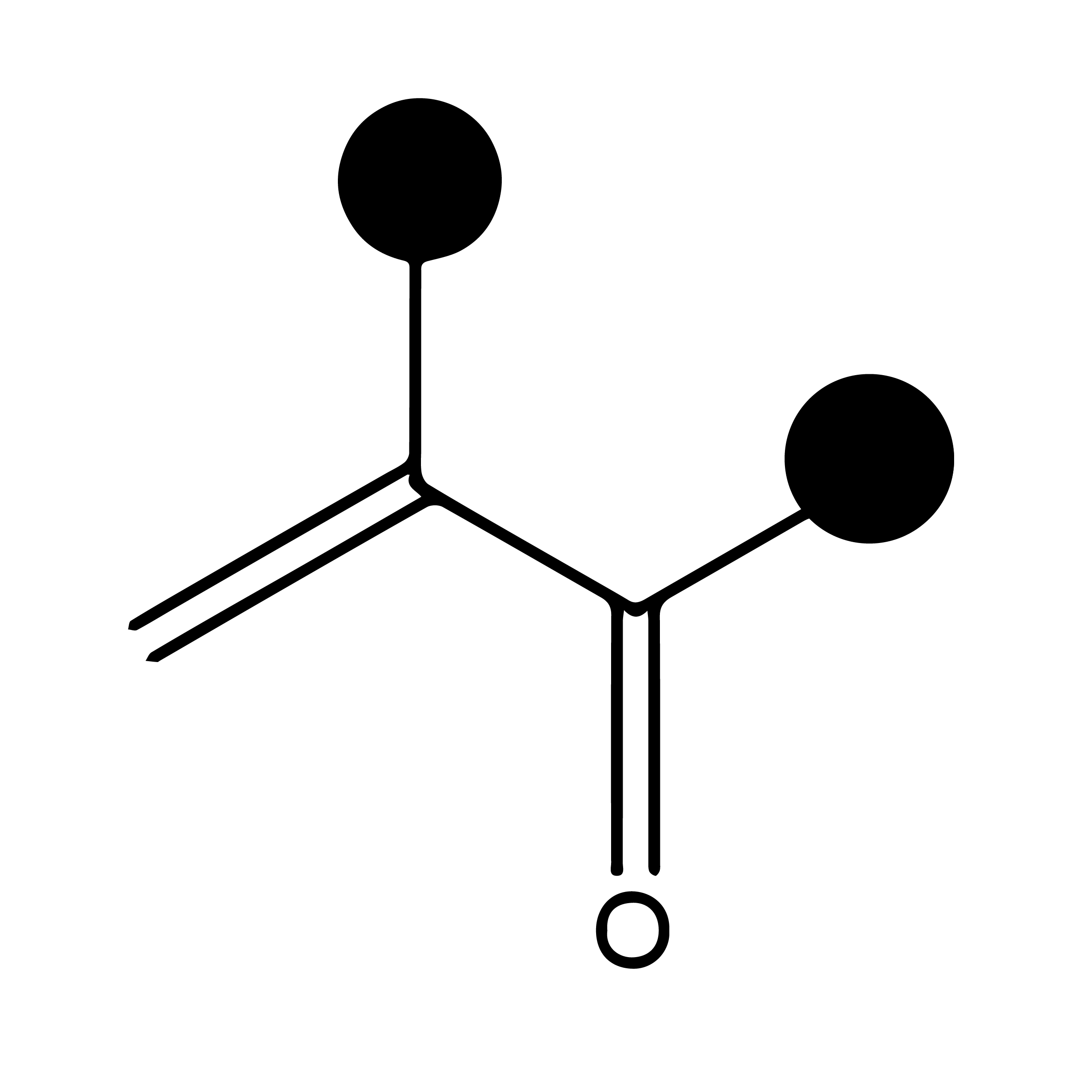

Acrylates

From 3D printing elastomers to contact lens materials, acrylate monomers and oligomers are essential building blocks for UV curable acrylic photopolymers. These materials are tailorable to a variety of functionalities and enhance the performance properties of additive manufacturing formulations.

Benefits of specialty acrylate monomers and oligomers

- Fast Cure Formulations: Acrylate monomers and oligomers facilitate rapid polymerization under UV light exposure, leading to fast curing times and more efficient printing overall.

- High Resolution: High-resolution prints are achieved by enabling precise control over polymerization kinetics and minimizing shrinkage during curing.

- Versatility in Formulating: To meet specific application requirements, we can adjust various parameters such as viscosity, curing speed, and mechanical properties.

- Excellent Surface Finish: Acrylate monomers and oligomers improve the surface finish of prints, minimizing the need for post-processing and improving overall print quality.

- Good Compatibility with Resins: Compatible with a wide range of resins and additives commonly used in 3D printing formulations, acrylates ensure stability and consistency in the printing process.

- Low Odor and Low Toxicity: Specialty acrylate monomers and oligomers are designed to have low odor and low toxicity, providing a safer working environment for users and reducing potential health risks associated with exposure to volatile organic compounds.

- UV Stability: Acrylates offer UV stability, ensuring that printed objects maintain their structural integrity and performance properties with UV exposure.