What is fused granulate fabrication?

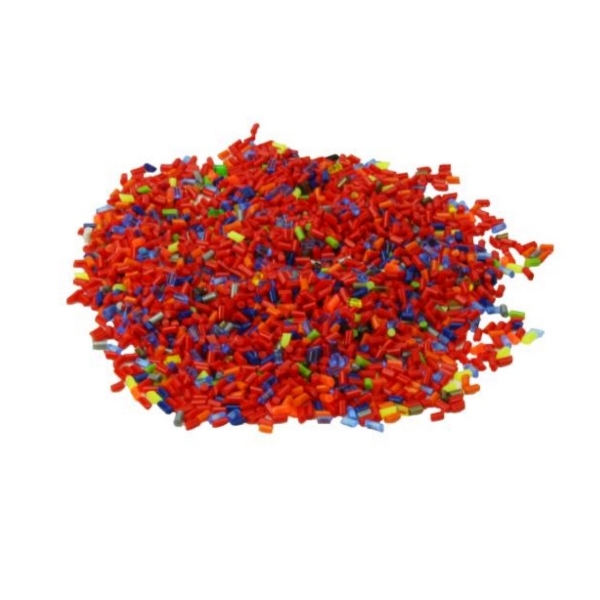

Fused granulate fabrication (FGF) is is an extrusion-based additive manufacturing method that utilizes granular materials (pellets), typically plastics or composites, as the primary feedstock for printing. A heated nozzle melts and extrudes the granules layer by layer to 3D print intricate and customized objects.

What are the advantages of FGF over other 3D printing methods?

FGF is an emerging technology which stands out with its precise, high-speed plastics extrusion capability compared to fused filament fabrication (FFF).

A key strength of FGF vs. other additive manufacturing methods is that it can effectively utilize a wide range of commercially available pellets in the form of plastic or composite granulates. The ease of access to compatible materials makes FGF a cost-effective and easily scalable option with numerous applications.

What expertise is required to scale FGF operations?

Precisely because FGF is compatible with such a wide range of 3D printing materials, the technology comes with a more intricate printing process. Different materials necessitate custom process settings. This means that analyzing material processability for FGF requires a deeper technical understanding compared to Fused Filament Fabrication.

How does Mitsubishi Chemical Group support customers in the FGF space?

If you need a highly specialized FGF material for a specific application, it is understandable that you would be reluctant to purchase a large batch of materials without having the opportunity to test the pellets in situ. To reduce your risk, we have dedicated production lines that enable us to provide you with with smaller batches of compounds (up to 25 kg per batch) to test before you scale.

This way, we can work together fine tune your FGF materials and process in order to avoid common printing issues such as melt flow, bed adhesion, warpage/shrinkage, rigidity/flexibility, layer adhesion, etc.

Is it possible to use recycled materials for FGF?

Fused granulate fabrication is a 3D printing method that is highly compatible with recycled materials. We capture high-quality recycled raw materials from post-industrial and post-consumer waste streams for reprocessing into compounds for large scale FGF printing. Recycled FGF materials provide a financially attractive way to start with large scale granule printing.

Explore our selection of recycled FGF materials here.

All pellet extrusion products

Explore our wide portfolio of high-performance pellet materials for Fused Granulate Fabrication (FGF)

FGF ABS-X

FGF ASA-X

FGF CARBON-P

FGF Light Wood

FGF PIPG Glassfiber (19%)

FGF PIPG Glassfiber (30%)

FGF PLA Stone

FGF PLA-X³

FGF PP Glassfiber (30%)

FGF Recycled ABS-X

FGF Recycled ASA-X 20% Glassfiber

FGF Recycled CARBON-P

FGF Recycled PC-ABS

FGF Recycled PET-G

FGF Recycled PIPG

FGF Recycled PLA